I have had a lot of interest in my stainless fish spear this season. I would like to thank everyone that has checked them out and possibly purchased one.

What I would like to achieve in this blog is an understanding that I take a tremendous amount pride in everything I set forth to do. This product is one of my leading examples and a great way to showcase this. I run a small business that is based on my personal fabrication skills I have picked up along my journey. I welcome all criticism as positive feedback. Underneath this babble I will provide an inside scoop on what goes into an Evolution Spear. I have a price tag that I hope will seem respectable when I am finished. I do not sell them in stores or in online markets. You deal directly with me and It will be made personally for you. I like to keep track of where they go. I will always know the original owner. Where they go from there.....who knows! I can tell you one thing for sure. They will not show up in the scrap yard!

What I would like to achieve in this blog is an understanding that I take a tremendous amount pride in everything I set forth to do. This product is one of my leading examples and a great way to showcase this. I run a small business that is based on my personal fabrication skills I have picked up along my journey. I welcome all criticism as positive feedback. Underneath this babble I will provide an inside scoop on what goes into an Evolution Spear. I have a price tag that I hope will seem respectable when I am finished. I do not sell them in stores or in online markets. You deal directly with me and It will be made personally for you. I like to keep track of where they go. I will always know the original owner. Where they go from there.....who knows! I can tell you one thing for sure. They will not show up in the scrap yard!

Let the games begin

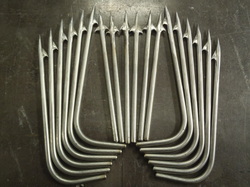

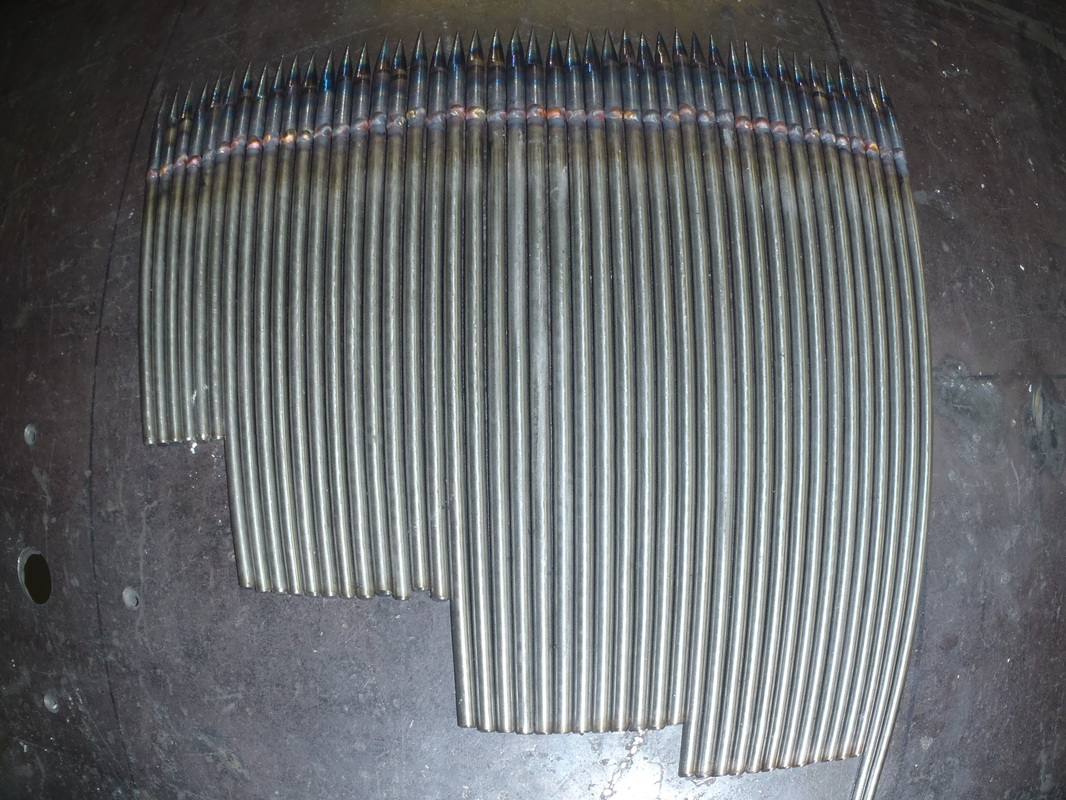

This is all the cut components for 6 spears.

5 of them are going to be 7 tine and 1 of them is a 9 tine.

This is all the cut components for 6 spears.

5 of them are going to be 7 tine and 1 of them is a 9 tine.

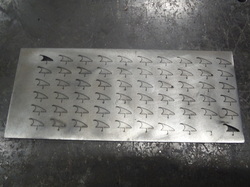

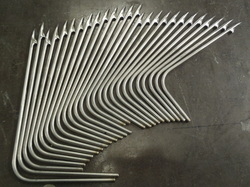

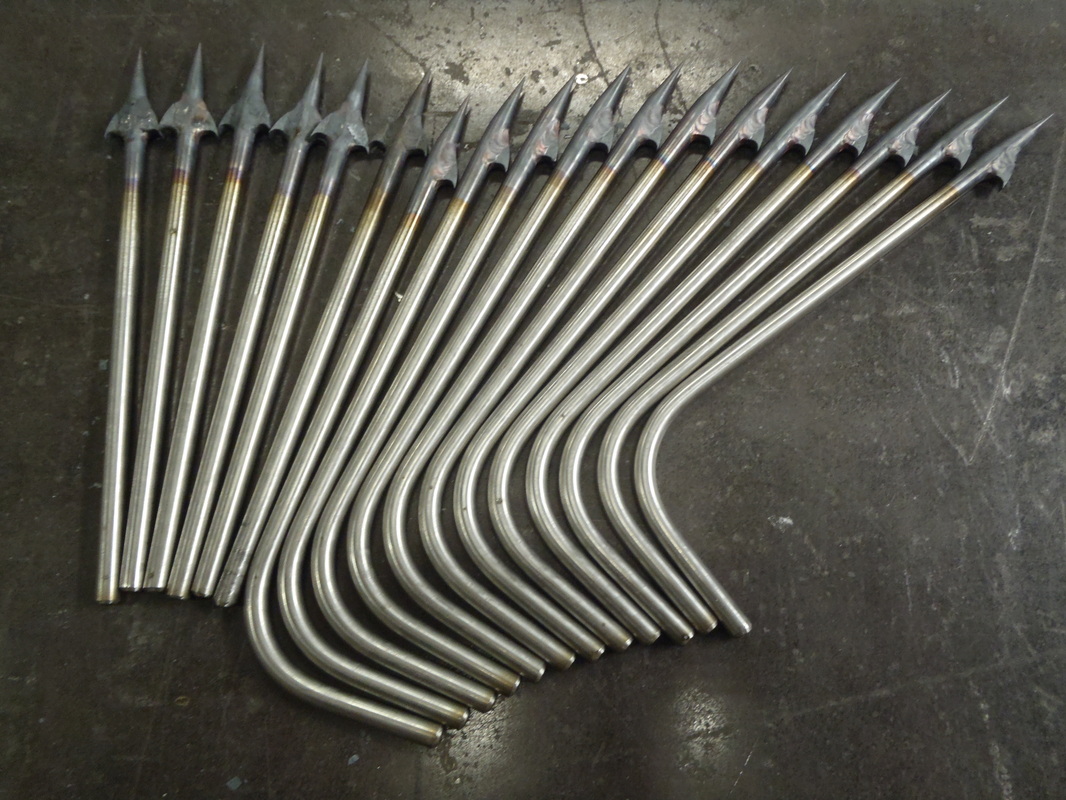

Here are the laser cut barbs before I pop them from their nest.

This is 1/8" tool steel in an annealed state. They will receive heat treat as an assembly with the tine.

This is 1/8" tool steel in an annealed state. They will receive heat treat as an assembly with the tine.

This concludes Day 1

All pieces cut and machining has begun.

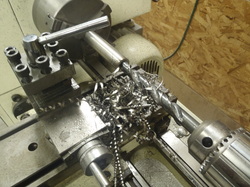

I kind of like the fisheye view......

All pieces cut and machining has begun.

I kind of like the fisheye view......

Day 2

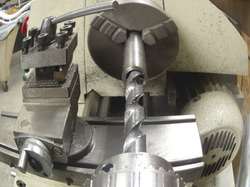

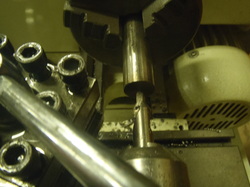

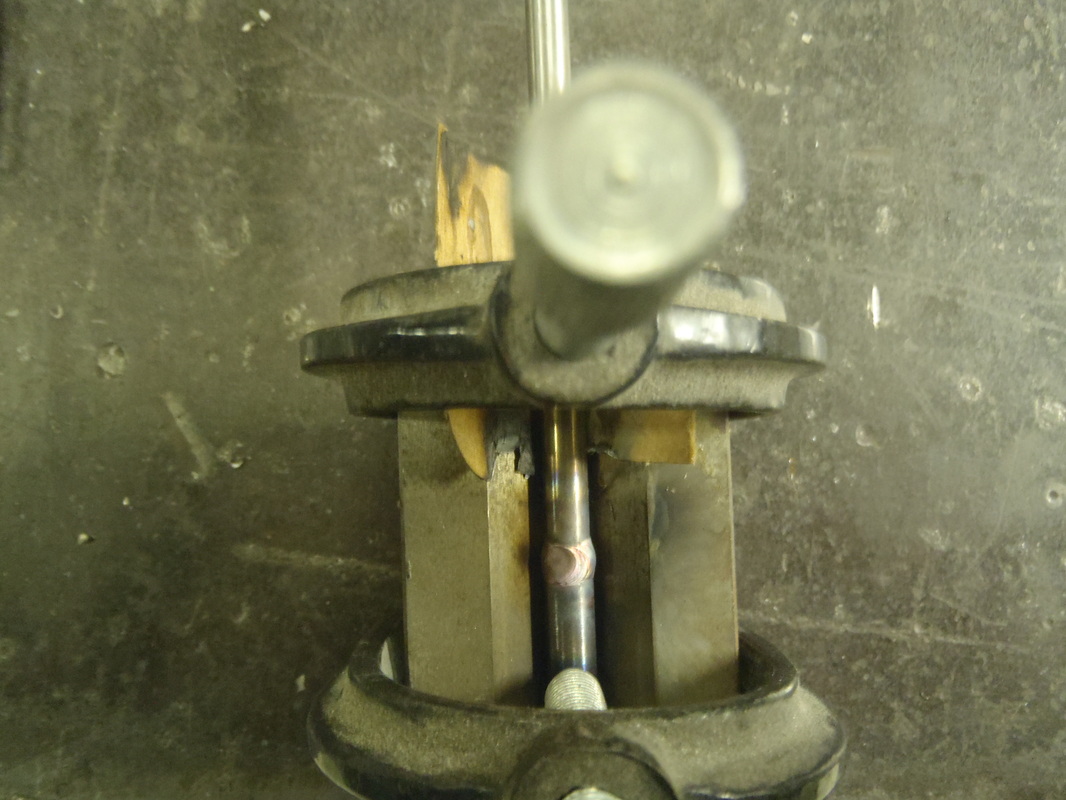

drilling the 1/4" hole for the center tine. The center tine is inserted 3/4" and then welded around the outside.

Then the taper is started. I will blend this after welding so it transitions smoothly.

Flip it around and drill a 1/2" hole for the handle. This process insures that the entire spear is perfectly inline.

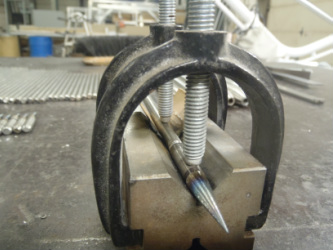

My next step is to begin welding the tool steel to the stainless. This is fixture welded to line them up perfectly.

This concluded day 2

Day 3

Turning weld down to hide the seam

Barbs being welded to each tine

Now the hard part. making them work.....and very cool looking

That's good enough for today.

Day 4

The tines are trimmed to the right length. I begin with the center 3 and then work my way out. The bend can now be calculated.

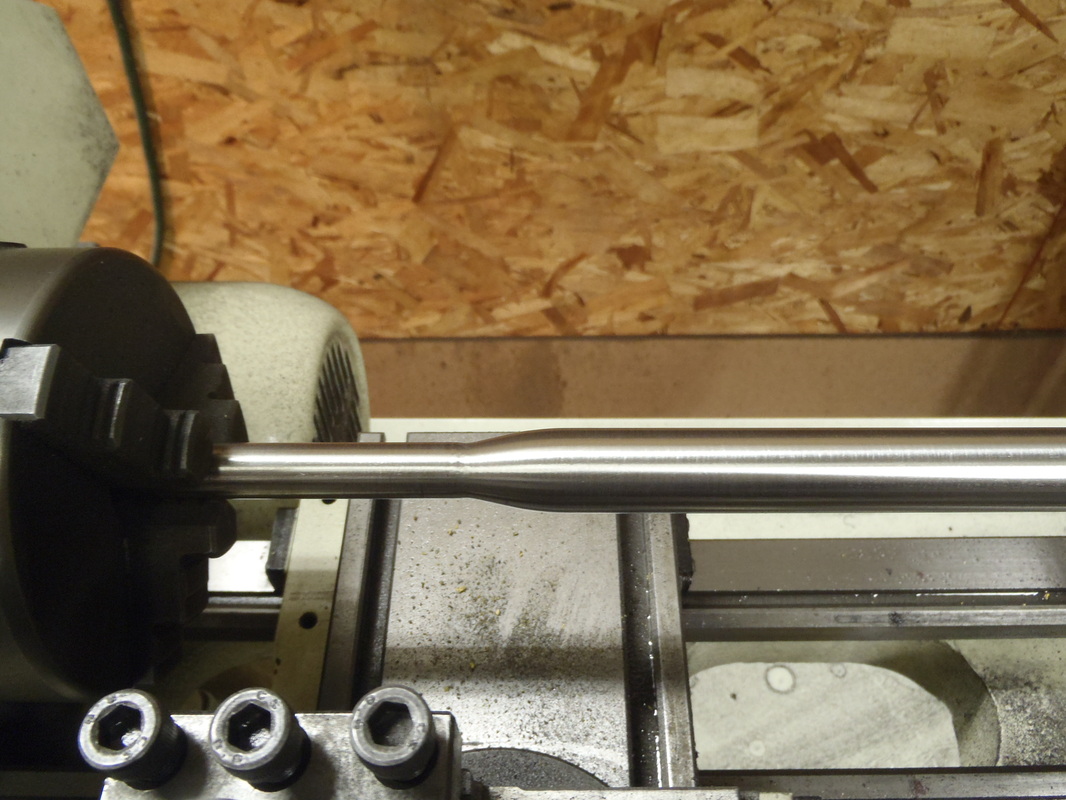

center tine is fully welded and then spun to check for run out as well as machine the seam smooth.

*I have decided that the weld can be left on with my new bracing that intersects here. It will hide it and provide strength.

*I have decided that the weld can be left on with my new bracing that intersects here. It will hide it and provide strength.

Remaining tines are bent, barbs welded out and metal finished.

Day 5

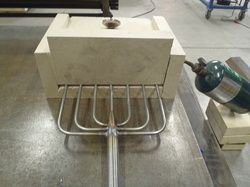

Today I will get all 6 spear heads tacked together. I will then focus on each one individually from now on out.

This is my way of creating a personalized product.

This is my way of creating a personalized product.

The 9 tine is going to be a monster!

Top braces are tacked on

This also can be used as a line tie so the fish can be inverted when hoisted back up.

This also can be used as a line tie so the fish can be inverted when hoisted back up.

New for 2013 is a curved cross brace that connects directly to the center tine.

This follows the same arc of the tine tips and makes each tine the same effective length.

This follows the same arc of the tine tips and makes each tine the same effective length.

The entire head is now fully welded and immediately heat treated.

I will have more on this process later.

you can now see the seam between the 2 metals again.

I will have more on this process later.

you can now see the seam between the 2 metals again.

After the hardening process the are heat tempered to 400 deg. for 1/2 hr. twice.

This makes them less brittle and less likely to fracture if they impact a hard surface.

This makes them less brittle and less likely to fracture if they impact a hard surface.

Handle is attached and the weld is blended .

Not safe at all, but sure works good.

This s a true test on how straight the entire spear is. And out of round shows up here and I can tune it.

Not safe at all, but sure works good.

This s a true test on how straight the entire spear is. And out of round shows up here and I can tune it.

Line loop is formed and attached to the end.

spear is complete and will get painted black

RSS Feed

RSS Feed