What I would like to achieve in this blog is an understanding that I take a tremendous amount pride in everything I set forth to do. This product is one of my leading examples and a great way to showcase this. I run a small business that is based on my personal fabrication skills I have picked up along my journey. I welcome all criticism as positive feedback. Underneath this babble I will provide an inside scoop on what goes into an Evolution Spear. I have a price tag that I hope will seem respectable when I am finished. I do not sell them in stores or in online markets. You deal directly with me and It will be made personally for you. I like to keep track of where they go. I will always know the original owner. Where they go from there.....who knows! I can tell you one thing for sure. They will not show up in the scrap yard!

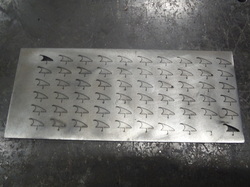

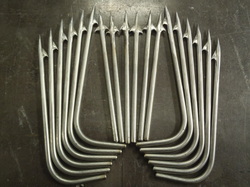

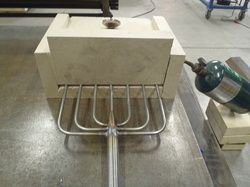

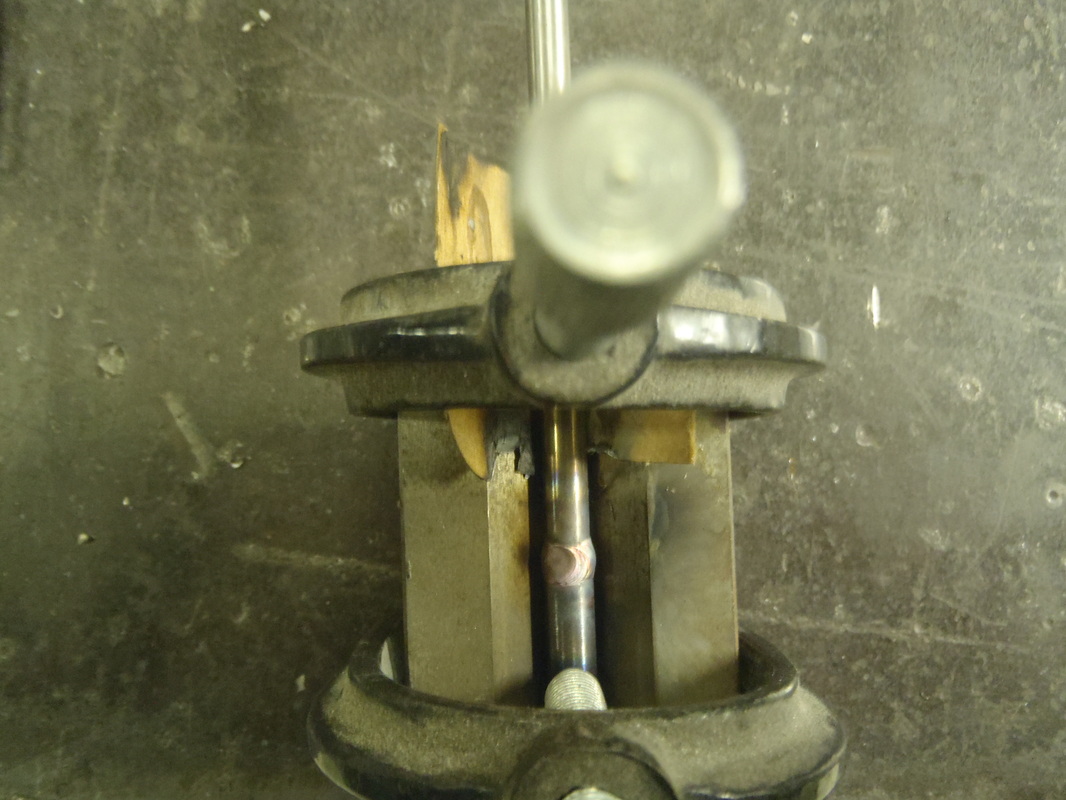

This is all the cut components for 6 spears.

5 of them are going to be 7 tine and 1 of them is a 9 tine.

This is 1/8" tool steel in an annealed state. They will receive heat treat as an assembly with the tine.

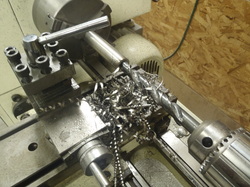

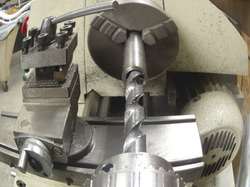

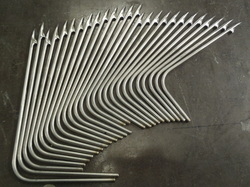

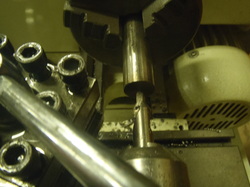

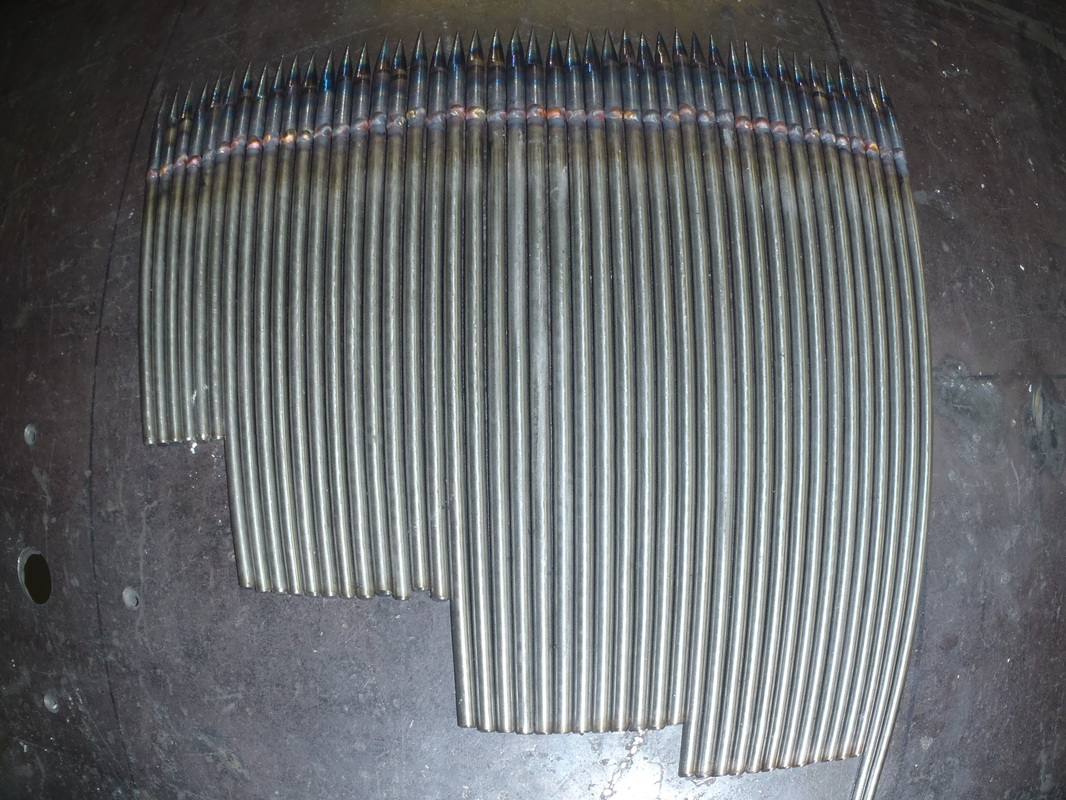

All pieces cut and machining has begun.

I kind of like the fisheye view......

Day 2

Day 3

Day 4

*I have decided that the weld can be left on with my new bracing that intersects here. It will hide it and provide strength.

Day 5

This is my way of creating a personalized product.

This also can be used as a line tie so the fish can be inverted when hoisted back up.

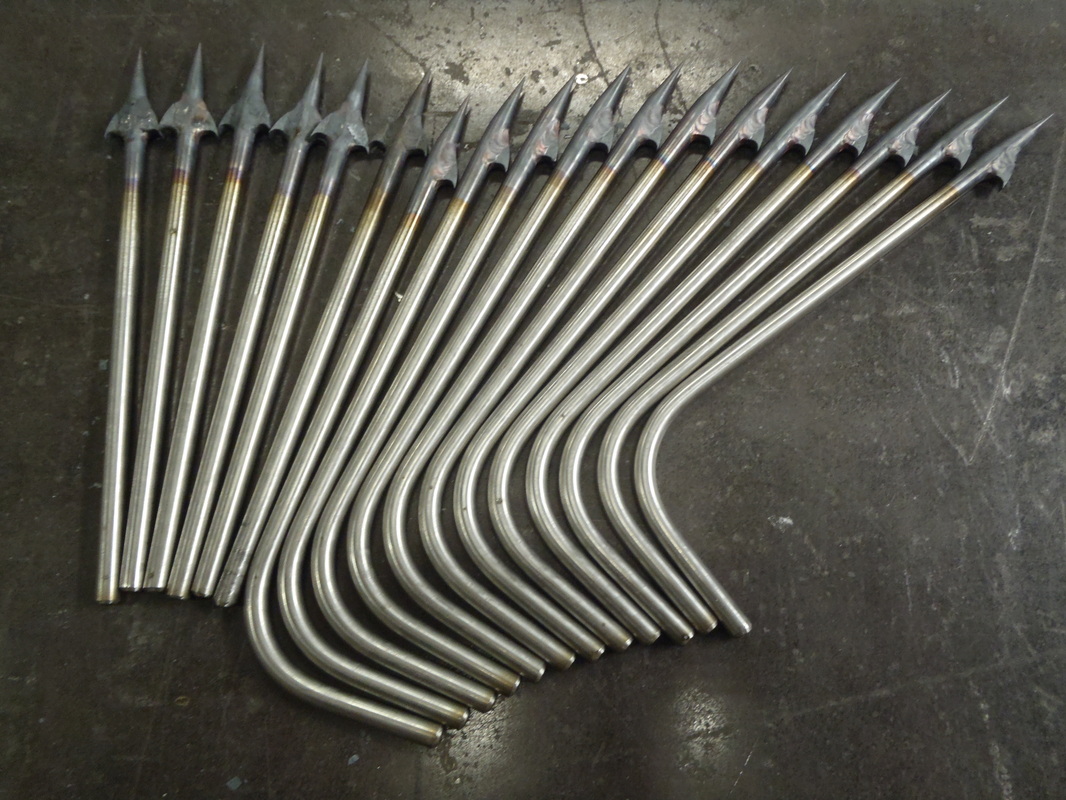

This follows the same arc of the tine tips and makes each tine the same effective length.

I will have more on this process later.

you can now see the seam between the 2 metals again.

This makes them less brittle and less likely to fracture if they impact a hard surface.

Not safe at all, but sure works good.

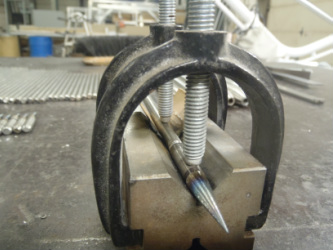

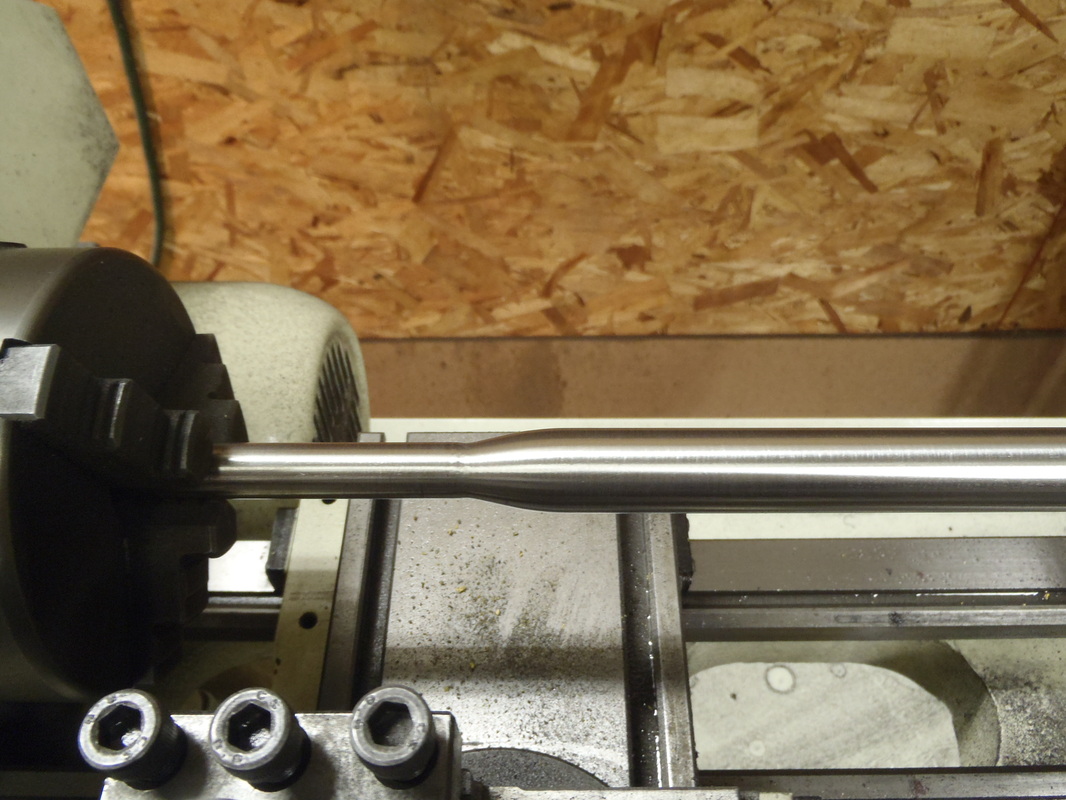

This s a true test on how straight the entire spear is. And out of round shows up here and I can tune it.

RSS Feed

RSS Feed