Higgins Marine Metals LLC Gyro installation project

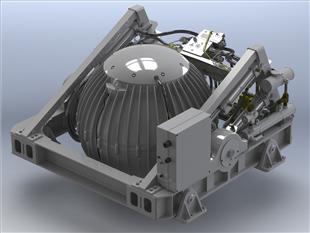

We recently were given the challenge to install a Seakeeper gyro in a 60' Aluminum work boat that has been converted to a live aboard cruiser. A gyro virtually eliminates low speed boat roll which provides a perfectly stable atmosphere within the vessel. No more sea sickness to the passengers and crew.

The gyro-dynamics involved in this process create force that counteract input from the boat. In order to perform effectively it must be mounted securely to the hull. The owner has chosen where he would like it to placed and we went to work designing a platform to attach to. It is not necessary to place the gyro on the center line of the hull or does it matter for and aft. It is suggested to keep it aft of mid-ship as to not affect boat control.

The gyro-dynamics involved in this process create force that counteract input from the boat. In order to perform effectively it must be mounted securely to the hull. The owner has chosen where he would like it to placed and we went to work designing a platform to attach to. It is not necessary to place the gyro on the center line of the hull or does it matter for and aft. It is suggested to keep it aft of mid-ship as to not affect boat control.

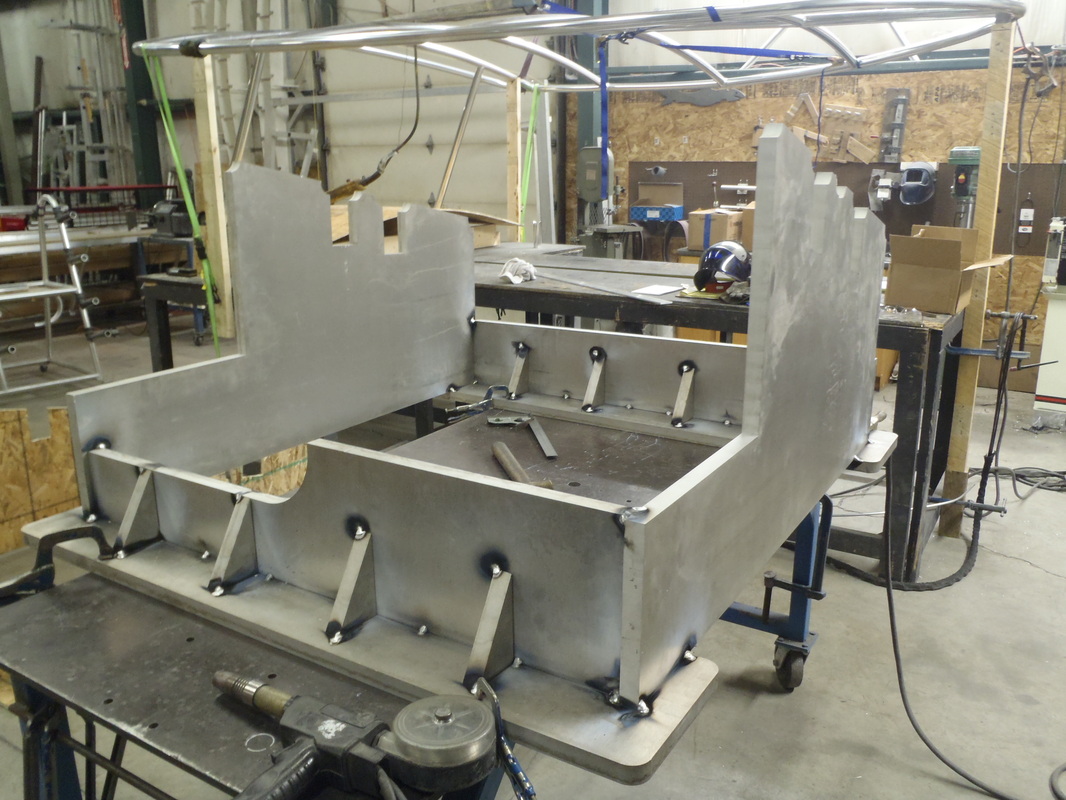

1" 6061 aluminum plate

After a design was perfected and proved to fit using plywood it was sent to a local waterjet facility that was capable of handling the 1" thick plate we were going to create it from.

This is the plate back from cutting. 90% of the plate was utilized with very little waste.

This is the plate back from cutting. 90% of the plate was utilized with very little waste.

Assembly

The mount is assembled with tack welds and then fully restrained to my 1/2" thick steel table to ensure the mounting surfaces are stay flat and true.

Mounting hole transfer jig

Seakeeper provides this jig fixture that is used to check flatness and also locate the 32 holes used to attach the gyro.

At this point the platform is completely welded out and ready for installation.

At this point the platform is completely welded out and ready for installation.

Installation of the mounting bracket

A handy feature with this work boat is its lifting crane located on the aft corner of the deck.

The bracket is approximately 400 lbs. at this point. It will be around 420 lbs. after it is installed with it's gussets.

The bracket is approximately 400 lbs. at this point. It will be around 420 lbs. after it is installed with it's gussets.

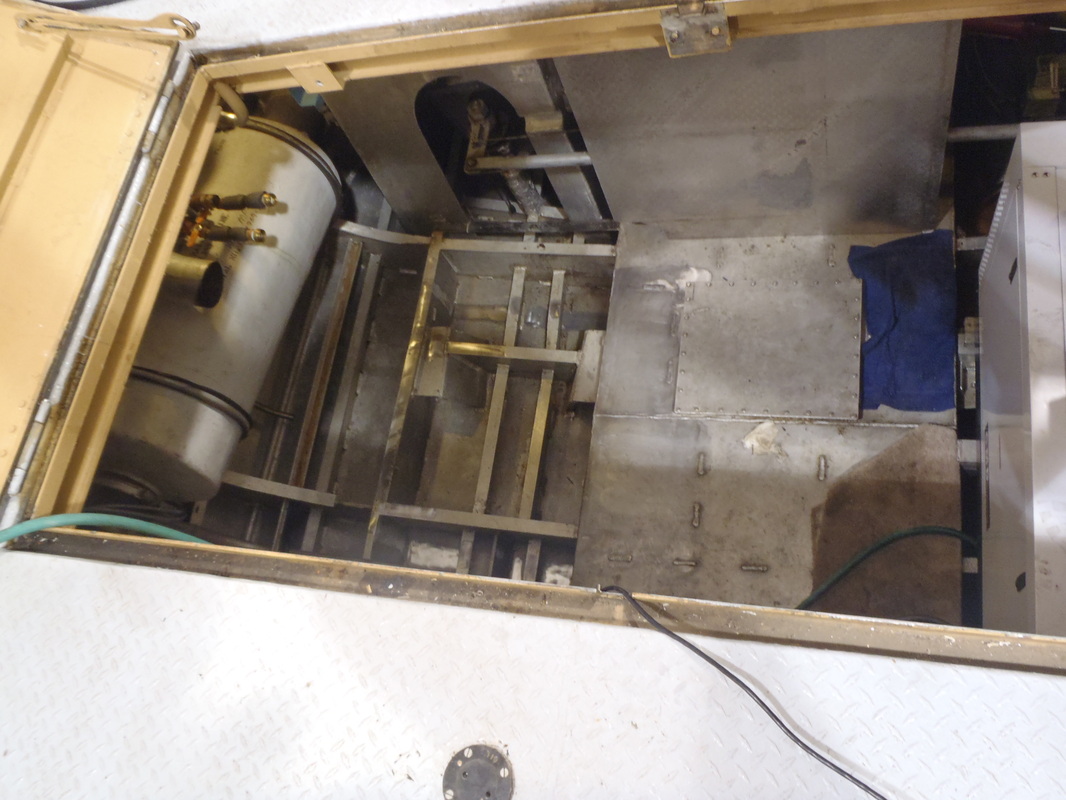

Welding to the hull

Once the Bracket is in position and perfectly square it is fully welded to the hull. The provided Jig is installed to help maintain flat surfaces.

The owner wished to have it located to starboard in order to provide access to the transom and clearance for generator access located on the port side.

All Gyro loads will be transmitted through Longitudinal girders and Traverse frames that make up the structure of the hull bottom

The owner wished to have it located to starboard in order to provide access to the transom and clearance for generator access located on the port side.

All Gyro loads will be transmitted through Longitudinal girders and Traverse frames that make up the structure of the hull bottom

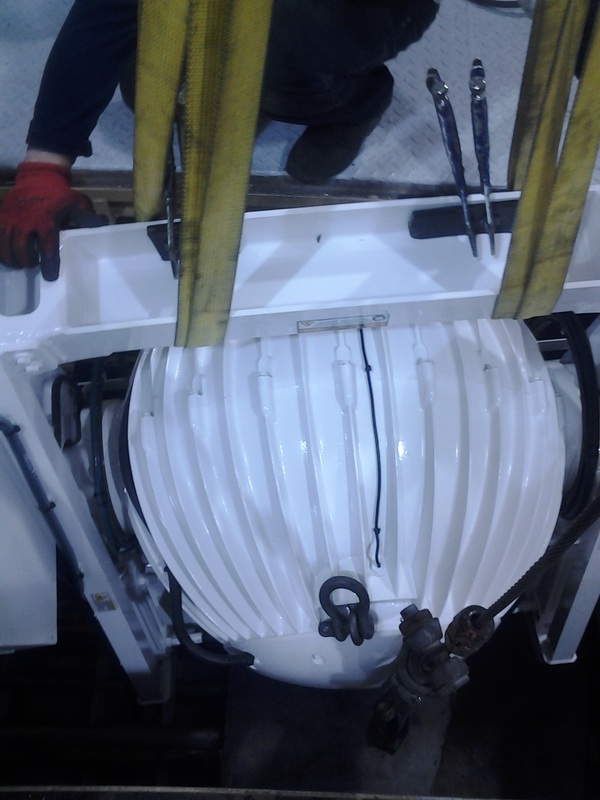

Installing the Gyro

The gyro is prepped and rigged to be lifted into place.

The size of the Gyro was wider than the compartment opening so we were forced to rotate the gyro and slip it in on end in order to clear the hatch.

The Gyro weighs in at 3000lbs. and is extremely sensitive to damage.

This required a lot of carefully made decisions to complete this task.

The size of the Gyro was wider than the compartment opening so we were forced to rotate the gyro and slip it in on end in order to clear the hatch.

The Gyro weighs in at 3000lbs. and is extremely sensitive to damage.

This required a lot of carefully made decisions to complete this task.